IPAF Global Safety Report 2025

The analysis of accident data to identify the primary causes of fatalities and major injuries in the global powered access industry.

Introduction

In 2024, IPAF introduced its first digital Global Safety Report, transitioning from the traditional downloadable PDF format to a more interactive, accessible online version. The digital version proved to be a great success and easily surpassed our expected target number of views of 4,500. As of April 2025, we have now recorded 8,503 views from 109 countries.

The 2024 Global Safety Report was shortlisted for two prestigious awards:

In the second digital edition of the Global Safety Report, we analyse the accident data from 2024. Data is collected on Mobile Elevating Work Platforms (MEWPs), Mast Climbing Work Platforms (MCWPs) and Construction Hoists (CHs). The data in the report is for fatal and major incidents only.

This high-quality publication is the result of the collaborative efforts and shared expertise of IPAF’s International Safety Committee (ISC) and Safety & Technical Department. IPAF would like to thank the members of the ISC for their time and effort in analysing anonymised accident data and for their ongoing support in shaping other key IPAF safety resources. We also extend thanks to our members and diligent people around the world who continue to report their accidents via the IPAF Accident Reporting Portal or anonymously.

Introductory statement from Alana Paterson, Chair of the IPAF International Safety Committee and Head of Health, Safety & Environment at Taylor Woodrow:

As I come to the end of my two-year tenure as Chair of the IPAF International Safety Committee and we publish this year’s Global Safety Report, I find it a fitting moment to reflect. With over 20 years of experience in health and safety across construction and engineering - several of those focused specifically on powered access, I’ve witnessed significant evolution in how we approach working at height and equipment safety.

Powered access continues to be one of the safest and most efficient methods for working at height. However, we still see serious, and at times, tragic incidents around the world. These serve as a stark reminder of why the work of IPAF and its committees is so vital. The data collected through the IPAF Accident Reporting Portal not only informs this report but also guides the focus of our collective efforts, whether that’s developing guidance documents, toolbox talks, technical innovations, hire standards, or more.

One of the most impactful areas of this work is training. The IPAF training team, supported by the Training Committee, has made tremendous strides in updating existing courses and launching new ones, ensuring they are accessible in multiple languages to reach a truly global audience.

While operator and technician education remain a cornerstone, I urge those responsible for putting people to work, such as employers, managers, and supervisors, to reflect on their own training needs. Courses like MEWPs for Managers and its international equivalents have been available for years, yet uptake remains lower than it should be. Those who have completed the course often speak to its value in deepening understanding of MEWP safety. Similarly, the newer Hoists and Mast climbers for Managers course has received excellent feedback - one of my colleagues recently described it as “hugely beneficial.”

So I leave you with two calls to action:

- Report every MEWP incident, no matter how minor, via the IPAF portal or ePAL app. This data is essential to our mission.

- Invest in competence, not just for operators, but for everyone involved in planning and supervising work at height.

Together, we can continue to raise the bar for safety in powered access and protect those who rely on this equipment every day.

Executive Summary

IPAF began collecting global accident data in 2012, and since then, we have seen a steady increase in the number of reports submitted year-on-year. This rise reflects growing industry recognition of the value of accident reporting in facilitating IPAF to produce new training materials and courses, safety and technical resources and annual safety campaigns to improve powered access safety globally.

This year’s Global Safety Report focuses on fatal and major injury data from 2024*. While the number of reported incidents saw a slight decrease (170 reports in 2024 compared to 201 in 2023), a significant reduction in fatalities was recorded (100 in 2024, down from 135 in 2023).

IPAF continually seeks to penetrate new markets, sectors and regions to understand and offer solutions to reduce incidents and accidents involving powered access equipment. In line with this goal, we would expect to see a rise in the number of accident reports from a broader range of countries. However, the number has remained the same – in 2023 we received reports from 26 countries and in 2024 we received reports from 26 countries.

In 2024, just over half of all reports originated from the United Kingdom (UK), followed by the the United Arab Emirates (UAE) and the United States of America (US). While some regions have a solid reporting culture, there is a noticeable gap in submissions from other countries or regions where a higher number of reports might be expected – particularly given the number of machines present.

This year’s report focuses on fatal and major injury data only, however, it is equally important to consider the number of near-miss reports IPAF receives. In 2024, IPAF received 368 near-miss reports from 19 countries, involving 408 people. This compares to 2023, where 384 near-miss reports were received from 20 countries, involving 428 individuals.

IPAF encourages anyone who owns or uses powered access equipment to report accidents and near misses, no matter how big or small, as every data point helps build a clearer picture of global safety trends. As a reminder, all accident reports are anonymised and confidential and IPAF does not share any accident data. Accident reporting has now become a lot easier with the evolution of the IPAF ePAL app.

Accident analysis revealed that most incidents occurred on construction sites followed by arboriculture and electrical sectors. Construction sites can be busy places with many different pieces of powered access equipment working simultaneously in the same area, which could account for the high number of accident reports.

Analysis of the most common types of powered access equipment involved in incidents revealed that again 1b (vehicle), then 3a and 3b were the most common to be involved in accidents. 1b (vehicles) include vehicle mounted platforms, e.g., truck and van mounted equipment, which are becoming increasingly popular as a means of carrying out temporary work at height.

The 2025 Global Safety Report reflects IPAF’s ongoing commitment to providing clear, reliable accident data for the powered access industry. We hope this year’s report will be as impactful as the last, further contributing to reducing accidents involving powered access equipment globally.

In conclusion, the 2025 Global Safety Report underscores IPAF’s commitment to transparent and anonymous accident reporting and the advancement of safety standards in the powered access industry. Through collaborative efforts and pioneering approaches, IPAF remains wholly committed in our mission to reduce incidents and promote accident reporting as this facilitates IPAF in deciding upon safety campaigns and technical guidance on a global scale, helping powered access industry workers get home to their families and loved ones.

*Data is correct at the time of writing the Global Safety Report.

Key Findings

Key Findings

The 2024 accident data identified that the top three causes of accidents were overturns, entrapment and falls from the platform.

26

Countries & Regions

The number of countries that reported was 26; the same as 2023.

211

People

There were 211 people involved in incidents, a decrease of 12.1%.

100

Fatalities

There were 100 fatalities, a decrease of 26% on 2023.

- Construction

- Arboriculture

- Electrical

- Rental activity

- Facilities management service

- Other

- Telecommunications

- Manufacturing / logistics

- United States

- Other

- United Kingdom

- Rebublic of Korea

- Brazil

- Australia

- China

- Spain

- 1b

- 3a

- 3b

- Unknown

- No machine involved

- Other

- Telehandler

- Mast Climbing Work Platform

Top Six Fatal & Major Incident Trends

Electrocution and Electric Shocks

IPAF's definition of electrocution and electric shock:

Electric shock

- When a person comes into contact with an electrical energy source, electrical energy flows through a portion of the body causing a shock.

Electrocution

- A person has died because of contact with electricity.

Working near energised power lines poses significant health and safety risks when not adequately controlled. Incidents of electrocution or electric shock can lead to death or major injuries. Transmission and distribution power lines can cause electrocution through direct contact or arcing, with higher voltage lines increasing the risk. However, it is important to understand that the risks of electrocution and electric shock are just as likely on lower voltage power lines.

We generally consider power lines to be overhead and, for the most part, they are. However, it is a matter of perspective and depends on where the platform is positioned. Power lines can sometimes be beneath or adjacent to the MEWP platform or hidden by trees and vegetation.

Incidents of contact or arcing of electricity on MEWPs have a high fatality outcome, which means that most incidents nearly always end in fatalities.

In 2024 we saw a similar trend in incidents compared to 2023. The USA submitted the most reports, mainly because of electrical power line infrastructure, the high volume of powered access equipment in the country and a solid reporting system via the Occupational Safety and Health Administration (OSHA).

Incidents involving electrocutions/shocks are preventable with proper planning. If there are going to be electrical sources in the vicinity of where you will be working, a risk assessment needs to consider the following (this list is not exhaustive):

- Evaluation of the site conditions in advance and identification of the specific locations of overhead and underground power lines (in certain countries there are apps available for this).

- Liaison with other contractors who may be working on site at the same time.

- Use of satellite imagery to determine access and egress routes.

- Marking/signage of electrical sources.

- Use of electrical detection devices that can sense electrical fields.

- Signage and adequate exclusion zones.

- Specialist equipment such as Insulated Aerial Devices (IAD) MEWPs.

- Spotters who are trained and have certification which is accepted by the Energy Supply Authorities.

- Trained and familiarised MEWP operators.

- Delivery of briefings on the dangers of working in close proximity to power lines.

- Means of raising the alarm.

- Communication systems.

- Emergency procedures and rescue plans.

- Suitable PPE with electrical protection capabilities.

Electrocutions and Electric Shock Incidents Analysis – 2024

- A 31% decrease in electrocution and electric shock reports, with 27 incidents recorded in 2024 compared to 39 in 2023.

- A 33% decrease in fatalities, with 20 deaths reported compared to 30 in 2023.

- A 30% reduction in people involved (31 people), compared to 42 in 2023.

- Reports came from 7 countries, with the USA accounting for 70% of all incidents, followed by Spain and France.

- The arboriculture industry was the most affected sector in 2024, with 8 fatalities and 1 major injury (29%). This was followed by the electrical sector (22.6%) and the construction industry (22.6%).

- 52% of incidents involved a 1b (vehicle-mounted) MEWP, largely due to their widespread use in arboriculture. 3b MEWPs accounted for 29%.

- Roads and highways were the most common locations for electrocution and electric shock incidents in 2022, 2023, and 2024.

Global Safety Campaign 2023

IPAF’s 2023 Global Safety Campaign was titled “High Voltage!” The campaign was supported by various publications relating to the safe use of MEWPs in the vicinity of power lines.

Resources

Electrocutions & Electric Shocks

In 2024, reports were down 31% on the previous year. A 28% decrease in the number of people involved. Fatalities decreased by 33% compared to 2023.

27

Reports

Decrease of 28% compared to 2023.

7

Countries

The USA accounted for 70% of all incidents, followed by Spain and France.

31

Persons involved

Decrease of 28%, with 43 people involved in 2023.

20

Fatalities

33% decrease compared to 2023.

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static), push-arounds

Other

Unknown or no machine involved

Electrocution by Industry Sector

Electrocution by Location

Resources available:

The Safe Use of MEWPs in The Vicinity of Power Lines

View on ipaf.orgToolbox Talk: Avoiding Contact with Power Lines

View on ipaf.orgAndy Access: Keep Clear of Cables

View on ipaf.orgAndy Access Short: Keep Clear of Cables (video)

View on YouTubeIPAF Webinar: High Voltage! Safety Campaign 2023

View WebinarThe Safe Use of MEWPs to Manage Trees and Vegetation

View on ipaf.org

Falls From The Platform

IPAF's definition of falls from the platform:

- Person(s) have fallen from the work platform.

- Person(s) have fallen from another structure (roof, tree) directly after exiting the work platform.

- Person(s) have been ejected from the work platform as a result of the MEWP movement. This includes travel of the MEWP, and catapult following the MEWP becoming snagged.

Since IPAF began collecting global accident data in 2012, falls from the platform have consistently ranked among the top five most common types of incidents involving powered access equipment. Despite ongoing safety campaigns, guidance, and training, these incidents continue to occur year after year – often with tragic consequences.

IPAF recommends never to take shortcuts and to always follow the safe working procedures in accordance with your safe system of work and risk assessment. Failing to follow these safety measures can increase the risk of falls from the platform.

Falls from height are entirely preventable with the right planning, Personal Fall Protection Equipment (PFPE) and behaviour. The industry must continue to push for higher standards, greater accountability and a culture where safety is never compromised.

Ways to reduce the risk of falls from the platform

Work at height is a high-risk activity and needs to be planned and performed safely. Effective planning includes:

- Risk assessments are carried out by competent personnel who can identify hazards and use appropriate control measures.

- The development of a Safe System of Work (SSoW) which is understood by everyone involved in the work at height task.

- Selecting the most appropriate equipment – where there is any doubt, professional site surveys should always be used. Many IPAF members offer professional site surveys; use this link to find a provider Members Directory | IPAF.

- Monitoring the work at height by spotters or nominated ground rescue personnel who have been familiarised with the MEWP’s ground controls and emergency/auxiliary lowering system.

- Challenging unsafe behaviour, such as standing on guardrails, or not using Personal Fall Protection Equipment (PFPE) in boom type MEWPs.

- A documented rescue plan which is understood by all those involved in task and rehearsed at regular intervals.

- The use of a full body harness with an adjustable restraint lanyard and a karabiner connected to a manufacturer approved anchorage point in the platform.

Accidents can happen; however proper planning minimises the likelihood.

Operators of powered access equipment often contribute to these incidents due to:

- Taking shortcuts and not following the agreed SSoW.

- Being complacent i.e., having the attitude that nothing will go wrong.

- Failing to wear or correctly attach PFPE in boom type MEWPs.

- Incorrect machine selection.

- Overreaching the platform guardrail, which can be caused by incorrect machine positioning or incorrect MEWP selection.

- Operating the MEWP from the ground control position for normal use.

IPAF recommends that PFPE is worn in boom type platforms, mainly due to the catapult effect. There is significantly less likelihood of the catapult effect in vertical type MEWPs, therefore the wearing of PFPE will be the outcome of a job-specific risk assessment conducted by a competent person, or if local legislation requires PFPE in all MEWPs.

A scissor lift is a work platform designed for occupants to move and walk around on. However, there are several risks to consider if PFPE is worn with the lanyard connected to a manufacturer-approved anchorage point:

- The operator may be unable to move to the four corners of the platform to visually check beneath them for hazards before lowering the platform.

- If there are multiple platform occupants, there could be a tripping hazard due to trailing lanyards on the platform floor.

- If an operator intends to reverse when in the elevated and stowed position, they cannot check the blind spot behind them without disconnecting their lanyard.

- If an operator intends to extend or retract the extension deck, they may be unable to as they are attached to an anchorage point.

- If platform occupants are unable to work in a safe position and find it necessary to lean out or overreach, they should stop work immediately.

Selecting the correct MEWP for the task can reduce the need to lean out or overreach. Additionally, all personnel in the MEWP platform must wear suitable PFPE in accordance with their risk assessment.

IPAF strongly recommends that a professional site survey is carried out to ensure the correct MEWP is selected and positioned safely, eliminating the need to lean or overreach from the platform.

Falls have also occurred when MEWPs have been impacted, snagged, or experienced mechanical or technical failure. This highlights the critical importance of operators carrying out a thorough pre-use inspection before using the equipment, or when taking over a MEWP from another operator.

Falls from Platform Incident Analysis – 2024

- A 44% decrease in falls from the platform, with 23 reports in 2024 involving 26 people. In 2023, there were 41 reports and 33 fatalities.

- A 39% reduction in fall-related fatalities, with 20 deaths reported in 2024.

- Facilities management accounted for the highest proportion of incidents (27%), followed by construction (19.2%) and electrical work (15.4%).

- A 70% increase in the number of countries reporting accidents. Reports came from 12 countries, with the USA accounting for 31%, and both the UK and Republic of Korea each contributing 12%.

- Falls most occurred from 3b MEWPs (38%), followed by 1b vehicle-mounted (27%) and 3a scissor lifts (19%).

Global Safety Campaign 2022

The 2022 Global Safety Campaign was “Don’t Fall for it!”

The campaign identifies key causes of falls from the platform and provides advice about how to avoid associated hazards. The key safety messages are:

Plan thoroughly – Conduct a proper MEWP site survey/risk assessment, select the correct machine for the task and use trained operators, supervisors and managers.

Know your machine – Operators should be trained on the machine type they are using and familiarised on the specific model. Operators should assess if the machine is suitable for the task and conditions, and adequate in terms of reach, articulation and load-bearing capacity. Machine knowledge includes whether PFPE should be used and, if so, what type, and how to attach it.

Clip On! – If PFPE is required, all occupants of the platform must attach their lanyards to the correct anchor point. Ensure occupants’ movement within the platform is possible while their lanyards are attached, and do not move the machine or elevate the platform until, and unless, all occupants’ lanyards are attached.

Set-up and manoeuvre the machine/platform effectively – Occupants should never need to overreach, unfasten PFPE, step on or climb on guardrails, or otherwise extend the safe working envelope of the platform. Ensure vertical type MEWPs are well-positioned and repositioned as necessary throughout the job, to allow easy access to the area of work to be undertaken.

Stay inside the platform with lanyard(s) attached to a manufacturer approved anchorage point – The guardrails of the platform are the primary fall prevention method and define the operational envelope of the machine being used. Always stay inside the platform with the lanyard karabiner attached to a manufacturer approved anchorage point. Where there is a requirement for PFPE, occupants must wear it. Do not exit the platform at height; unclip/exit only on completion of work when the machine is safely in the stowed position.

Falls From The Platform

In 2024, reports of falls from the platform decreased by 44%, and there was a 39% reduction in fatalities. Reports came from 12 countries: a 70% increase on 2023.

23

Reports

Decrease of 44% on 2023.

12

Countries

Increase of 70% on 2023.

26

Persons involved

Decrease of 42% on 2023.

20

Fatalities

Decrease of 39% on 2023.

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static), push-arounds

Other

Unknown or no machine involved

Falls From The Platform by Industry Sector

Falls From The Platform by Location

Resources available:

MEWP Catapult Effect

View on ipaf.orgSafe Use of MEWPs to Manage Trees and Vegetation

View on ipaf.orgFall Protection in MEWPs (H1)

View on ipaf.orgSafe Use of MEWPs in Public Areas

View on ipaf.orgAndy Access: Don't Fall For It

View on ipaf.orgAndy Access: Attach Your Lanyard

View on ipaf.orgDon't Fall For It! Targeted Safety Campaign

View on ipaf.orgToolbox Talk: PFPE Pre-Use Check

View on ipaf.org

Entrapment

IPAF's entrapment definition:

Entrapment is a situation in which the operator or occupant of a MEWP becomes trapped or crushed between the MEWP controls or platform guardrails and an immovable object or external structure.

Most incidents of entrapment happen when the platform is elevated, however incidents can still occur when the platform is in the stowed/transport position. Operators of powered access equipment and platform occupants need to remain vigilant and always be aware of what is going on around them.

Ensuring the safety of MEWP operators and platform occupants is essential while they are working at height. The level of supervision required will depend on the specific situation. For example, two small scissor lifts working in the same area may be adequately monitored by one nominated ground rescue person. However, the same scissor or boom lift working in an area where one cannot be safely observed will require an increased level of monitoring or additional nominated ground rescue persons. Users (those in control of MEWP operations) must remember that when entrapment incidents occur, the time taken for persons to become aware of and react to the entrapment situation is critical – rapid response can be the difference between life and death, and every second counts.

Ways to reduce the risk of entrapment

What does the user need to do to minimise the risk of entrapment? All work at height should be properly planned. Part of the planning stage will be the completion of a risk assessment looking at the task and the working environment and should also include identifying potential crushing/entrapment areas. If there is a foreseeable risk of entrapment identified, then MEWPs with secondary guarding systems should be considered. Secondary guarding systems are readily available on 3b type (mobile booms) MEWPs and are now becoming available on 3a type (mobile verticals) MEWPs in some regions. If secondary guarding is required, you should consider contacting the MEWP rental company or the MEWP manufacturer.

If secondary guarding is fitted to the MEWP, then the MEWP operator should be familiarised with the specific system that is fitted. The secondary guarding system should also be a part of the pre-use inspection. IPAF recommends that pre-use inspections are recorded, either on paper or digitally. Holders of the IPAF ePAL app can record and share their pre-use inspections in the app.

What precautionary measures should MEWP operators take? Before operating, an operator should assess the proposed working area to identify potential crushing areas/hazards.

During operation, observation is crucial. The operator should always look up before elevating, look around before moving, and look down before lowering. Maintaining good observational skills whilst operating reduces the risk of incidents occurring.

Entrapment Incident Analysis - 2024

- A 75% increase in entrapment reports, with 28 reports in 2024, compared to 16 in 2023.

- More than 70% of all entrapment incidents occurred in the construction industry, (in 2023 there were 11 incidents, 68.7%). This was followed by facilities management and rental activity.

- A 62% increase in entrapment fatalities from 2023 to 2024, from 13 in 2023 to 21 in 2024.

- Reports came from 11 countries, with Hong Kong and the USA each accounting for nearly 18%, and the Republic of Korea contributing 14%. In 2023, 9 countries reported.

- An 87% increase in the number of people involved, with 28 in 2024, compared to 15 in 2023.

- Entrapments most occurred on 3a MEWPs (54%), followed by 3b MEWPs (43%).

Entrapment

In 2024, IPAF received 28 reports of entrapment incidents, a 75% increase from 2023 (16 reports). The reports came from 11 countries and involved 28 people. Of these, 21 fatalities occurred, indicating that entrapment incidents are often fatal.

28

Reports

Increase of 75% on 2023.

11

Countries

A 22% increase on 2023.

28

Persons involved

Increase of 87% on 2023.

21

Fatalities

Increase of 62% on 2023.

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static), push-arounds

Other

Unknown or no machine involved

Entrapment by Industry Sector

Entrapment by Location

Resources available:

F1: Familiarisation

View on ipaf.orgGood Practice Guidance for Reducing Trapping/Crushing Injuries to People in MEWPs

View on ipaf.orgThe Safe Use of MEWPs in Public Areas

View on ipaf.orgGuidance on Emergency Rescue

View on ipaf.orgRescue of Persons from MEWPs

View on ipaf.orgToolbox Talk: MEWP Rescue Plan

View on ipaf.orgToolbox Talk: MEWP Rescue Procedures

View on ipaf.orgAndy Access: Overhead Obstructions

View on ipaf.org

Overturns

IPAF's definition of an overturn is:

Permanent loss of stability of the MEWP, so that the MEWP has overturned or partially overturned. A MEWP partially overturned will be resting on an external structure and not have all ground points (wheels, stabilisers or outriggers) in contact with the ground.

Overturns were the most common type of incident in 2024, resulting in 11 fatalities and 19 major injuries.

Although overturns accounted for the greatest number of incidents, the fatal incident rate (FIR) was lower compared to entrapment (28 fatalities) and falls from the platform (20 fatalities).

This accident data was a major contributing factor into IPAF’s decision to focus the 2025 Global Safety Campaign on overturns – Stop Overturns! Safety Starts on the Ground.

This is not just a “spike” in overturn incidents involving powered access equipment; this type of incident has remained prominent over the past decade.

Key scenarios where overturns have been recorded include:

- Travelling mobile boom and mobile vertical MEWPs across unsuitable ground, whether in the elevated or stowed position.

- Setup or positioning of 1b-type MEWPs (including vehicle-mounted, trailer-mounted, and spider lifts).

- Travelling 1b (tracked) MEWPs over uneven ground with outriggers fully retracted.

- Travelling 1b (tracked) MEWPs with tracks in the retracted/narrow position over uneven terrain.

Planning is critical in ensuring the safe operation of a MEWP. During the planning stage, a competent person should undertake a risk assessment, which should include a detailed evaluation of the ground conditions where the MEWP will be travelled and used.

Underestimating the suitability of the ground and surface to support the MEWP can lead to a MEWP overturn, potentially resulting in major injury or death – not only for those in the platform, but also for those nearby.

Past incidents have included fatalities and injuries to members of the public and other workers struck by an overturning MEWP. These risks underscore the importance of proper planning, assessment and preventive action before any work at height is carried out.

Overturns Incident Analysis – 2024

- A 12.5% decrease in overturn incidents reported, with 21 reports received, compared to 24 reports in 2023.

- A 9% decrease in people involved in overturn incidents (30 people), compared to 33 people in 2023.

- 7 countries submitted reports, down 7%. The USA accounted for 58% of all incidents, followed by the Republic of Korea (13%) and Germany (13%).

- A 56% reduction in fatalities, with 11 fatalities reported in 2024, compared to 25 fatalities in 2023.

- The most common type of MEWP to overturn in 2024 was 1b with just over 40%. This was followed by 3a (33%) and 3b with 10%.

- Most overturn incidents occurred in the construction industry (nearly 60%), followed by the electrical and arboriculture sectors, each accounting for 16.7%.

The IPAF Global Safety Campaign for 2025 (Stop Overturns! Safety Starts on the Ground) is supported by various guidance including a new guidance document – The Assessment of Ground Conditions and Supporting Structures for the Safe Use of MEWPs.

Overturns

In 2024, reports of MEWPs overturning decreased by 12.5% to 21 incidents, and fatalities decreased by 56%. Seven countries reported these incidents, a 7% decrease on 2023. Overall, 30 people were involved in incidents.

21

Reports

Decrease of 12.5% on 2023.

7

Countries

Decrease of 7% on 2023.

30

Persons involved

Decrease of 12% on 2023.

11

Fatalities

Decrease of 56% on 2023.

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static), push-arounds

Other

Unknown or no machine involved

Overturns by Industry Sector

Overturns by Location

Resources available:

Guidance on the Assessment of Ground Conditions and Supporting Structures

View on ipaf.orgWind Rating – Using MEWPs in the Wind

View on ipaf.orgConsequence of Overloading the Platform

View on ipaf.orgToolbox Talk: Never Attach a Banner to a MEWP

View on ipaf.orgToolbox Talk: MEWP Ground Conditions

View on ipaf.orgAndy Access: Unsafe Ground

View on ipaf.orgAndy Access: Use Spreader Pads

View on ipaf.orgMEWP Catapult Effect

View on ipaf.org

Hit by Falling Object

IPAF's definition of being hit by a falling object is:

“Person(s) have been struck while in the platform, from a falling object above them”.

MEWPs are not fitted with overhead protection systems, so platform occupants are susceptible to falling objects from above. Given the terminal velocity of a falling object is around 120mph (193km/h) in air, the consequences of impact to the human body can be catastrophic. This can lead to major injuries or fatalities for the platform occupant(s), or significant damage to the equipment.

In addition to protecting themselves, platform occupants must also prevent tools or materials from falling from the platform and potentially injuring people working below them in other equipment, or at ground level. Note: the accident statistics shown below represent major injuries and fatalities to platform occupants.

To minimise the risk of being hit by falling objects, IPAF strongly recommends:

- The assessment of overhead hazards before starting work.

- The use of tethers or tool lanyards to secure objects.

- Head protection with a chinstrap to be always worn when using powered access equipment.

- Clearly defined exclusion zones with adequate signage.

All incidents involving fallen objects – whether or not they result in injury or damage – should be reported.

Hit by Falling Object Incident Analysis - 2024

- A 50% decrease in incident reports, with 9 reports received.

- A 75% increase in fatalities, with 7 deaths reported.

- An 86% increase in the number of people involved in incidents (13 people).

- 4 countries submitted reports, down 50% year-on-year. The USA accounted for 77% of all incidents (10 reports), followed by the Republic of Korea and Brazil (1 report each).

- The most common type of MEWP to be involved in this type of incident was 3b (mobile boom). There were 7 reports in total (nearly 54%).

- 69% of incidents occurred in the construction industry (9 reports – 5 fatalities and 4 major injuries). Arboriculture accounted for 31% (4 reports).

- To summarise, the most common trend for incidents of falling objects is people using 3b type MEWPs on construction sites.

All work at height needs to be planned and risk assessed, however the work environment can change quickly, especially on construction sites where there are lots of simultaneous operations involving various types of equipment. Always be aware of any work above the platform which could potentially lead to falling objects.

MEWP operators should assess their work environment before starting work and during the course of the shift, to look for identifiable hazards. If there is a risk of objects/materials falling from above, then the work should not commence. Additionally, if there is a foreseeable risk of objects falling during work (or, if an incident has occurred), the work activity should be stopped and the issue reported.

Hit by Falling Object

In 2024, incidents involving people being hit by falling objects saw fatalities jump by 75% compared to 2023, totalling 7. 69% of these incidents occurred in the construction industry, highlighting a significant area of concern.

10

Reports

Decrease of 50% on 2023.

4

Countries

Decrease of 33.3% on 2023.

13

Persons involved

Increase of 86% on 2023.

7

Fatalities

Increase of 75% on 2023.

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static), push-arounds

Other

Unknown or no machine involved

Hit by Falling Object by Industry Sector

Hit by Falling Object by Location

Resources available:

Safe Use of MEWPs to Manage Trees and Vegetation

View on ipaf.orgBeware Falling Objects or Materials Striking the MEWP

View on ipaf.orgAndy Access: Beware Falling Objects

View on ipaf.orgPrevent Objects Falling From the Platform

View on ipaf.org

Inoperable Mechanical/Technical

IPAF's definition of Inoperable Mechanical/Technical is:

- The MEWP has been rendered inoperable or in unsafe condition.

- Includes components disconnecting (e.g. covers or bolts coming loose, wheels becoming detached from chassis)

- Includes hydraulic faults.

- Includes electrical/software faults.

Powered access equipment needs to be maintained, serviced and inspected in line with the manufacturer’s instructions and regional safety standards – this is the responsibility of the owner of the equipment, which is normally a rental company or an end-user. Failing to keep equipment in a safe, serviceable condition increases the likelihood of mechanical or technical failure during use and early component failure of equipment.

The user (who in most cases is the hirer of the equipment) is also responsible for ensuring the equipment is safe to use. They should ensure that the equipment has an in-date routine or periodical examination and there is evidence of the inspection/examination with the equipment.

Thorough examinations are not performed by the operator, they are carried out by a competent person, which is often a service engineer/technician from an equipment rental company, a third-party inspection company, or even the manufacturer. If it is not evident, or if it is out of date, the machine should be isolated and not used.

Operators should always carry out a pre-use inspection of the machine in accordance with the manufacturer’s instructions before use. IPAF recommends recording evidence of the inspection on the ePAL app. Performing a pre-use inspection can often identify things that can go wrong. Examples include:

- Low fuel level

- Low battery power

- Signs of leakage from hydraulic lines

- Damaged or malfunctioning equipment

- Components that are faulty or in poor condition.

If a fault is found it should always be reported and rectified before use.

Additionally, operators should always be familiarised with any equipment that is unfamiliar to them, so they understand the control functions and safety devices. Understanding the control functions and safety devices minimises the risk of machine failure/breakdown, which is often due to operators not knowing how a machine works or incorrect set-up.

Inoperable Mechanical/Technical Incident Analysis - 2024

- A 33% decrease in reports of fatal and major injuries relating to mechanical or technical failures on all types of powered access equipment, with 8 reports received. The USA and Malaysia entered 3 reports each.

- A 45% decrease in fatalities, with 6 fatalities reported.

- 7 countries submitted reports, which was a 12.5% decrease on 2023.

- 13 people were involved in these incidents: down nearly 32% from 2023.

- The facilities management sector accounted for the highest number of these incidents, with just over 30% of reports.

- 64% of incidents occurred on a 3a MEWP (9 reports), followed by 1b (vehicle) MEWP (2 reports) and 3b (1 report).

Inoperable Mechanical/Technical

In 2024, IPAF reports of mechanical or technical failures decreased by 33% to 8, and there was a 45% decrease in fatalities. Reports came from 7 countries, 12.5% less than 2023.

8

Reports

Decrease of 33% on 2023.

7

Countries

Decrease of 12.5% on 2023.

13

Persons involved

Decrease of 32% on 2023.

6

Fatalities

Decrease of 45% on 2023.

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static), push-arounds

Other

Unknown or no machine involved

Mechanical/Technical by Industry Sector

Mechanical/Technical by Location

Resources available:

Guidance for Major Inspections of MEWPs

View on ipaf.orgManaging the Safe Condition of MEWPs

View on ipaf.orgSafe On-Site Servicing of MEWPs

View on ipaf.orgAndy Access: Safe Workshop Servicing of MEWPs

View on ipaf.orgCAP Certification

View on ipaf.orgAndy Access: Don't Use a MEWP as a Crane

View on ipaf.org

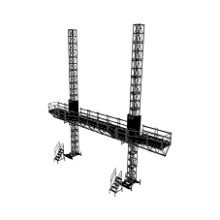

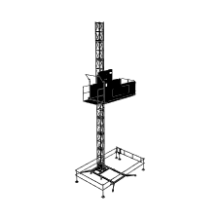

Mast Climbing Work Platforms (MCWPs) & Construction Hoists (CH)

Powered access equipment includes not only MEWPs, but also Mast Climbing Work Platforms (MCWPs) and Construction Hoists (CHs).

IPAF continues to see steady growth in new MCWP and CH Training Centres, as well as companies becoming IPAF members globally. This is an encouraging trend that we hope continues over the coming years.

Working Groups

Earlier this year, IPAF formed a new Working Group (WG) dedicated to developing Toolbox Talks for MCWPs and CHs. The group comprises six members from various regions around the world, representing both manufacturers and industry experts.

International Standards updates

There’s also been significant activity globally with revisions to international standards. IPAF was part of the WG involved in the revisions to:

Australian Standards

- Australian Standard AS2550.16 Cranes – Safe use Mast Climbing Work Platforms

- Australian Standard AS1418.16 Cranes (including hoists and winches) Mast climbing work platforms

- Australian Standard AS2550.7 Cranes – Safe use Builder’s hoists and associated equipment

- Australian Standard AS1418.7 Cranes – (including hoists and winches) Builder’s hoists and associated equipment

British Standards

- The draft of BS 7981:2025 Mast Climbing Work Platforms (MCWPs) – Selection, configuration, installation, maintenance, thorough examination and safe use – Code of practice, was open for public consultation (from 20 March to 20 May 2025). It is expected to be released in November 2025.

Canadian Standards (CSA) – no changes in 2024

European Standards

- The draft of EN 1495 Lifting Platforms. Mast climbing work platforms. This has now been completed and submitted for CEN enquiry

North American Standards:

The American National Standards Institute (ANSI) is in the process of periodic updates to the following standards:

- The Main Committee approved splitting the main A92.9 Standard into two - A92.9A for Design requirements and A92.9B for Safe Use/Training.

- A92.9A Design, Calculations, Safety Requirements and Test Methods for Mast-Climbing Work Platforms

- A92.9B Safe Use and Establishing Training Content and Administrative Requirements for Mast Climbing Work Platforms

- A92.10A Design, Calculations, Safety Requirements and Test Methods for Transport Platforms

- A92.10B Safe Use and Establishing Training Content and Administrative Requirements for Transport Platforms

- The ANSI/ASSE A10.4-2016 Standard covers safety guidelines for personnel hoists and employee elevators on construction and demolition sites. It sets specifications for the hoist structure, hoist enclosure, materials, machine used for driving, and landings and landing zones that make these components reliable over time.

- The ASME B30.23-2022 Standard is the safety standard for the construction, installation, operation, inspection, testing, maintenance, and use of cableways, cranes, derricks, hoists, hooks, jacks, and slings used to lift, lower, hold, or transport personnel.

- ANSI/ASSP A10.5-2020: Material Hoists Requirements

Accident data analysis

Recorded incidents with this type of equipment are relatively low. This could be because the number of units in operation globally is far less compared to the number of MEWPs in service. However, when incidents do occur, it can often result in multiple casualties because MCWPs and CHs are able to carry more people.

- IPAF received 4 reports (fatal and major), compared to 7 reports in 2023.

- 3 countries reported incidents in 2024, compared to 5 countries in 2023. Those countries were: UK, USA and Switzerland.

- There were 4 people involved in these incidents in 2024, which is 75% less than 2023.

- There was 1 fatality compared to 10 fatalities in 2023.

- All the incidents happened in the construction sector.

- 75% of incidents happened on a MCWP (3 reports), and 25% on CHs (1 report).

- The main cause of major injuries and fatalities:

- Overturns – 1 major injury

- Falls from height (not platform) – 1 fatality

- Contact with an object or person – 1 major injury

- Hit by a falling object – 1 major injury

- The United Kingdom – 2 reports

- The USA – 1 report

- Switzerland – 1 report

Mast Climbing Work Platforms (MCWPS) & Construction Hoists (CH)

4

Reports

Decrease of 43% on 2023.

3

Countries

Decrease of 40% on 2023.

4

Persons involved

Decrease of 75% on 2023.

1

Fatalities

Decrease of 90% on 2023.

People involved by category

Mast Climbing Work Platform

Passenger Hoist

Goods Hoist

Transport Platform Hoist

Personnel Hoist

Mast Climbing Work Platforms (MCWPS) & Construction Hoists (CH) by Industry Sector

Mast Climbing Work Platforms (MCWPS) & Construction Hoists (CH) by Location

Resources available:

Mast Climbing Work Platform (MCWP) Thorough/Frequent Examination

View on ipaf.orgToolbox Talk: MCWP Loading

View on ipaf.orgAndy Access: MCWP and Hoist Rescue Plan

View on ipaf.orgAndy Access: Do Not Interfere with Ties

View on ipaf.orgMilestones

IPAF’s Milestones for 2024

IPAF's ePAL App

Average of 85k users a month; 75k machine familiarisations recorded; almost 50k pre-use checks recorded in ePAL; over 800k views of safety information; over 25k clicks through the accident reporting site.

ePAL230,404 people trained via IPAF globally

The IPAF training programme is globally recognised, developed by leading industry professionals and available in multiple languages across a worldwide network of more than 900 IPAF Approved Training Centres.

View nowNew Operator Course addresses top 6 fatal incident trends in context

The IPAF MEWP Operator Training Course is for anyone who needs to safely and effectively operate a MEWP in any machine category.

View now