IPAF Global Safety Report 2024

Uncovering Trends and Exploring the Primary Causes of Fatalities and Major Injuries in Powered Access

Introduction

The IPAF Global Safety Report 2024 examines the primary causes of major injuries and fatalities during the operation of powered access machinery, including Mobile Elevating Work Platforms (MEWPs), Mast Climbing Work Platforms (MCWPs), and Construction Hoists (CH). Powered access equipment is widely regarded as one of the safest methods for enabling work at height. However, safety is dependent on effective management, supervision, and operator involvement throughout the planning and operation stages. IPAF continues to analyse data received through the Accident Reporting Portal and has subsequently delivered three global safety campaigns and one UK safety campaign since 2021.

Marking a strategic shift towards digitisation, this report represents an effort by IPAF to enhance accessibility while advancing its sustainability objectives, laying the groundwork for future editions. IPAF collaborates closely with its network of valued members, manufacturers, rental companies, distributors, contractors and users to identify emerging safety trends and challenges. Through data analysis and knowledge sharing, we drive targeted guidance and training initiatives, promoting safety campaigns on a global scale. We are proud to be working alongside our members in over 81 countries and regions, with plans for further expansion and global safety coverage in 2024 and beyond.

The production of the Global Safety Report follows a strict protocol to ensure quality. From its inception within the Safety & Technical Department to rigorous internal and external evaluations conducted by the International Safety Committee (ISC), each phase seeks to produce an informed, reliable and comprehensive report. The report details data on industry sectors, incident locations, countries where incidents occurred on all types of powered access equipment, and incidents by machine categories (1A, 1B, 3A, 3B), with a focus on Fatal and Major incidents only.

Since IPAF began collecting accident data in 2012, there has been a significant increase in reported incidents into the IPAF Accident Reporting portal, signalling increased reporting awareness around the world. While notable advancements were made in 2023 and are continuing in 2024 and beyond, there is still much work to be done to maintain momentum and continually improve safety standards in the operation of powered access machinery around the world.

Introductory statement from Alana Paterson, Chair of the IPAF International Safety Committee and Head of Health, Safety & Environment at Taylor Woodrow:

"As a safety professional I have been working in and around powered access equipment for more than 20 years, not only in the rental industry but also in construction and civil engineering, for me the use of powered access remains one of the safest forms of working at height, despite the incidents we experience. The volume of machine movements across the globe far outweighs the number of incidents we experience, which is small in comparison.

The work of IPAF and the IPAF International Safety Committee (ISC) is crucial in preventing these incidents. I urge everyone to report any incident involving powered access through the IPAF Accident Reporting Portal or the ePAL app. Capturing this information is essential for trend analysis and developing future safety campaigns, training, and standards.

In the past year, campaigns based on trends from the 2022 Global Accident Report have been successful. For example, the electric shock awareness campaign has led to increased reporting, as expected. The guidance document and campaign material have been widely viewed and downloaded. Our goal is to reduce electric shock incidents over time by raising awareness and taking action.

This report is the result of extensive data collection, trend analysis, and the hard work of the IPAF team and industry contributors. I extend my gratitude to the IPAF team and ISC members for their dedication to improving safety in the powered access industry.

Please use this report to educate and promote safety in the powered access industry, demonstrating our commitment to making operations safer worldwide."

Executive Summary

When exploring the subject of global MEWP, MCWP and CH safety, it's important to reflect on IPAF’s Accident Reporting journey from 2012 to the current day. In 2012, IPAF received 288 reports from 10 countries, documenting 34 fatalities. By 2023, this landscape had evolved significantly, with the number of reports increasing to 1022 from 42 countries, a 26.5% increase compared to 2022 (808 reports). This trend signals significant progress in reporting practices over the past decade, albeit whilst acknowledging the potential for underreporting, emphasising the need for continued improvement in safety practices.

Offering an overview of our latest findings, the 2024 Global Safety Report seeks to provide a clearer picture of the powered access industry. While there was an 11.7% decrease in Fatal and Major incident reports compared to the previous year, this decline contrasts with a rise in fatalities, highlighting the persistent safety challenges we must collectively overcome. Notably, the construction sector emerges as the most affected, with 44.9% of incident reports originating from this industry, a slight rise on 2022. Additionally, significant contributions to incident reports come from key countries such as the United States (44.4%), the UK (12%) and the Republic of Korea (11.1%).

Analysis revealed specific trends in MEWP categories involved in incidents, with 1b vehicles and 3a vehicles being the most common across various incident types. These findings reflect IPAF's commitment to transparent accident reporting and advancing safety standards in the powered access industry, highlighting the need for continued vigilance and improvement to mitigate risks and reduce incidents globally.

The main causes of incidents and accidents explored within IPAF’s Global Safety Report remain consistent and cover a variety of risks, including falls from the platform, overturns, electrocution, entrapment, MEWP/MCWP inoperable mechanical technical failure, and being hit by a vehicle or machine. These findings underscore the multifaceted nature of safety challenges in the powered access industry, necessitating targeted interventions and proactive measures to mitigate risks and enhance safety standards.

In conclusion, the 2024 Global Safety Report reaffirms IPAF’s commitment to transparent and anonymous accident reporting and the advancement of safety standards in the powered access industry. Through collaborative efforts and pioneering approaches, IPAF remains wholly committed in our mission to mitigate risks, reduce incidents, and promote safety campaigns and technical guidance on a global scale, helping powered access industry workers get home to their families and loved ones.

Key Findings

Key Findings

The main causes of incidents involving powered access equipment continues to be similar year on year. The top 3 lost time incidents for 2023 were falls from the platform, overturns and electrocutions.

26

Countries & Regions

The number of countries who reported was 26, a 10% decrease on 2022

216

People

There were 216 people involved in incidents, a decrease of 2%

128

Fatalities

There were 128 fatalities, an increase of 12% on 2022

- Construction

- Arboriculture

- Facilities management service

- Rental activity

- Other

- Electrical

- Telecommunications

- Manufacturing / logistics

- United States

- Rest of World

- United Kingdom

- Republic of Korea

- Germany

- Canada

- Italy

- Spain

- 1b

- 3a

- 3b

- Unknown

- Mast Climbing Work Platform

- No machine involved

- Other

- Passenger Hoist

Top Six Fatal Incident Trends

Electrocution and Electric Shocks

Working near energised power lines poses severe health and safety risks when not adequately controlled. Incidents of electrocution or electric shock can lead to death or major injuries. Transmission and distribution power lines can cause electrocution through direct contact or arcing, with higher voltage lines increasing the risk. However, it is important to understand the risks of electrocution and shock are just as likely on lower voltage power lines.

We generally consider power lines to be overhead and, for the most part, they are. However, it is a matter of perspective and dependent on where the platform is positioned. Powerlines can sometimes be beneath or adjacent to the MEWP platform or hidden by trees and vegetation.

Electrocution and electric shocks are often considered to be the same thing, in fact they are not, so what is the difference?

Electrocution:

Means a person has died because of contact with electricity; this can be caused by:

- Contact, arcing or flashover with a power line.

Electric shock can occur:

- When a person comes into contact with an electrical energy source. Electrical energy flows through a portion of the body causing an electric shock.

- Exposure to electrical energy may result in no injury at all or may result in devastating damage to body organs or death.

As displayed in the graphs below, most incidents of electrocution and electric shock have occurred in the arboriculture, construction, and electrical sectors. This has been the same pattern for many years.

Effective planning is essential for the safe operation of powered access equipment. When in use continual observation and vigilance by the operator to identify power lines can prevent accidents, saving lives.

Planning is critical and should include:

- Isolation of the power line wherever possible

- Risk assessments and a safe system of work including a safe exclusion zone

- Number of trained staff involved

- The location of the work to be carried out

- Assessment of the task and the surrounding landscape/infrastructure

- Access and egress to site

- Consideration of specialist insulated vehicles and equipment

- Spotter / banksman (with appropriate training)

- Communication system between the operator and the spotter

- Emergency procedures and rescue plan

- Engineering controls or warning devices such as devices that can detect electricity should be considered

Analysis of Electrocutions and Electric Shock incidents

- On average, the US submitted the most reports, accounting for 87% of incidents in 2023.

- In 2023, the Construction industry became the most common sector for incidents of electrocution and electric shock, with 4 fatalities and 8 major injuries.

- In 2023, 3b and 1b MEWPs were the most common type of equipment involved in incidents of electrocution and electric shock, likely due to their prevalent use in the construction industry.

- Roads and highways remained the most common locations for incidents in both 2023 and 2022.

Electrocutions & Electric Shocks

In 2023 reports were up 65% on the previous year. Double the number of countries reported and the number of people involved went up by 90%. Fatalities rose by 47% compared with 2022.

34

Reports

Increase of 70% on 2022

7

Countries

Increase of 133% on 2022

38

Persons involved

Increase of 90% on 2022

25

Fatalities

Increase of 47% on 2022

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, push-arounds, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static)

Other

Unknown or no machine involved

Electrocution by Industry Sector

Electrocution by Location

Resources available:

The Safe Use of MEWPs in The Vicinity of Power Lines

View on ipaf.orgAvoiding Contact with Power Lines Toolbox Talk

View on ipaf.orgAndy Access: Keep clear of cables

View on ipaf.orgAndy Access Short: Keep clear of cables (video)

View on YouTubeIPAF Webinar: High Voltage! Safety Campaign 2023

View WebinarThe safe use of MEWPs to manage trees and vegetation

View on ipaf.org

Falls From The Platform

Globally, falls from the platform rank among the top causes of death and major injury since IPAF began collecting accident data. This trend underscores the urgency of understanding its root causes and ensuring that planning for working at height is critical.

Whenever a work at height task is required, it should be thoroughly planned and risk assessed. Planning should always include the correct machine selections and trained operators who have been familiarised with the equipment. It is equally important that supervisors and managers are trained and understand the risks involved with all work at height tasks.

The use of powered access equipment requires competent planning and safe operation. Adhering to these recommendations reduces the likelihood of falls, emphasising the critical role of comprehensive planning in safeguarding against accidents. Effective planning involves:

- Risk assessment

- Development of safe work systems

- Selection of suitable MEWPs

- Training for operators

- Supervision

- Having documented rescue procedures in place which are practiced by rescue personnel

Platform (or MEWP and MCWP) operators often contribute to these incidents due to:

- Taking shortcuts and not following the agreed safe system of work

- Being complacent i.e., having the attitude that nothing will go wrong

- Failing to wear or correctly attach Personal Fall Protection Equipment (PFPE) in boom type MEWPs

- Overreaching the platform guardrail which can be caused by: -

- Machine positioning or

- Incorrect MEWP selection

Such behaviours significantly increase the risk of a fall from the platform resulting in death and serious injury, reflecting a dangerous mindset of invincibility.

Wearing appropriate PFPE can prevent falls, while correct machine selection and positioning may eliminate the need for risky manoeuvres such as overreaching and where this is observed by supervisors/management it should always be challenged.

Conducting pre-use inspections/checks and recording the inspection in the ePAL app, helps identify and mitigate mechanical or technical issues before they occur.

Analysis of Falls from the Platform

- On average, the USA and the Republic of Korea submitted the most reports in 2023 and 2022, with the USA taking first place in both years.

- The Construction industry saw a rise in the number of incidents in 2023, with 19 fatalities and 10 major injuries compared to 15 fatalities and 5 major injuries in 2022.

- 1b MEWPs were the most common type of equipment for falls from the platform in both 2023 and 2022.

- Analysing data for the most Lost Time Incidents by location, a similar pattern was observed in 2023 and 2022. Construction sites were the most common locations for incidents of falls from the platform, with 26 (fatal and major incidents) in 2023 and 24 in 2022. This was followed by Commercial Premises in second place for both years.

Falls From The Platform

In 2023, reports of falls from the platform increased by 2.8%. Seven countries reported, up from six in 2022. There were 46 cases and 36 fatalities, highlighting the often fatal nature of such incidents.

38

Reports

Increase of 2.7% on 2022

7

Countries

Increase of 16.7% on 2022

41

Persons involved

Decrease of 2% on 2022

29

Fatalities

Same as 2022

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, push-arounds, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static)

Other

Unknown or no machine involved

Falls From The Platform by Industry Sector

Falls From The Platform by Location

Resources available:

MEWP Catapult Effect

View on ipaf.orgSafe use of MEWPs to manage trees and vegetation

View on ipaf.orgFall protection in MEWPs (H1)

View on ipaf.orgSafe use of MEWPs in public areas

View on ipaf.orgAndy Access: Don't Fall For It

View on ipaf.orgAndy Access: Attach Your Lanyard

View on ipaf.orgDon't Fall For It! Targeted Safety Campaign

View on ipaf.orgPFPE Pre-Use Check Toolbox Talk

View on ipaf.org

Entrapment

Entrapment is a situation in which the operator or occupant of a MEWP becomes trapped or crushed between the MEWP controls or platform guardrails and an immovable object or external structure.

Entrapment incidents may occur not only when the MEWP is elevated but also in the lowered or stowed position, such as when an operator reverses or drives a MEWP under a low doorway or ceiling. MEWP operators and platform occupants should always remain vigilant, considering their surroundings and the ground and terrain the MEWP is travelling on is critical.

Precautionary measures, such as assessing the surroundings before elevating, lowering, or moving the platform, are crucial as accidents can occur unexpectedly. Operators should always walk the route prior to travelling to ensure that they and the MEWP can safely manoeuvre across, through it or under it.

Site managers and supervisors should include emergency lowering procedures in operator familiarisations and challenge operators and ground control rescue persons to demonstrate they can enact the rescue procedure.

To mitigate risks, global legislation increasingly mandates the requirement for a documented rescue plan for powered access equipment, underscoring the importance of both the ground control rescue person and the operator understanding emergency procedures for lowering the platform.

It is essential for operators to ensure accessibility to ground controls/emergency lowering controls are available and accessible before elevating the MEWP.

Entrapment incidents do not only occur when MEWPs are in an elevated position; they can also happen when MEWPs are in the lowered/stowed position or during loading and unloading from vehicles. In 2023, there were two fatalities and one major injury from incidents of entrapment while MEWPs were being travelled in the lowered position.

Control measures to avoid entrapment:

- Identify the work tasks at height, and at ground level

- Identify potential overhead obstructions which could lead to entrapment

- Determine if secondary guarding is required, fitted and the operator has been familiarised on it

- Verify that a rescue plan has been documented and specific to the MEWP in use

- The rescue plan has been communicated and rehearsed and the nominated ground rescue person is available

- Consider using slower speeds/finer controls when approaching the task area

- Operate the controls slowly and deliberately

- Use a grounds person (banksman) to supervise MEWP movement when in confined areas

Analysis of Entrapment Incidents for 2023

- In 2023, the most common countries for incidents involving entrapment were the UK and the Republic of Korea. This shows a change from 2022, when the top countries were Canada, the UK, Italy and the UAE, indicating no consistent pattern between the two years.

- When comparing the data between 2022 and 2023 for incidents of entrapment in Industry Sectors, a similar trend was observed. The Construction industry saw 13 incidents in 2022 (76.5%), which decreased to 10 incidents (66.7%) in 2023.

- The most common type of MEWP for incidents of entrapment in 2023 was 3a, which is frequently used in the construction industry, making it the most common industry sector.

- Entrapment incidents are often fatal. In 2023, there were 16 incidents, 13 of which resulted in fatalities. In 2022, out of 17 incidents, 11 were fatalities.

Global Safety Campaign 2024

The International Powered Access Federation (IPAF) announced the launch of its Global Safety Campaign for 2024 at the IPAF Summit held in Copenhagen, Denmark, titled "CRUSHING CAN KILL!" The third Global Safety Campaign released during IPAF Head of Safety and Technical Brian Parker’s tenure aims to raise awareness and reduce entrapment and crushing incidents involving MEWPs, which have resulted in numerous fatalities and injuries over the past decade.

Reflecting on the campaign's release, IPAF Head of Safety and Technical Brian Parker, stated: "We're not just launching a Global Safety campaign; we're reaching out to the individuals who stand on the front lines of safety every day—the MEWP operators and rescue personnel. Our aim is to give them the knowledge and tools they need to navigate their work environments safely and confidently. By ensuring that this campaign resonates with those directly using the platform, we're taking an important step toward reducing and preventing entrapment and crushing related incidents."

Entrapment

In 2023, IPAF received 16 reports of entrapment incidents, a slight decrease from 2022. The reports came from 9 countries and involved 15 people. Of these, 13 fatalities occurred, indicating that entrapment incidents are often fatal.

16

Reports

Decrease of 5.9% on 2022

9

Countries

Same as 2022

15

Persons involved

Decrease of 12% on 2022

13

Fatalities

Increase of 18% on 2022

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, push-arounds, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static)

Other

Unknown or no machine involved

Entrapment by Industry Sector

Entrapment by Location

Resources available:

F1: Familiarisation

View on ipaf.orgGood practice guidance for reducing trapping/crushing injuries to people in MEWPs

View on ipaf.orgThe safe use of MEWPs in public areas

View on ipaf.orgGuidance on emergency rescue

View on ipaf.orgRescue of persons from MEWPs

View on ipaf.orgMEWP rescue plan Toolbox talk

View on ipaf.orgMEWP rescue procedures Toolbox Talk

View on ipaf.orgAndy Access: Overhead Obstructions

View on ipaf.org

Overturns

Incidents involving MEWPs overturning have remained prominent over the past decade. Long-term data spanning 10 years consistently places overturns as the second most common incident type after falls from platform. This trend still persists in both 3-year and 1-year (2023) data, prompting a closer look into the causes.

Factors that may contribute to MEWP overturns:

- Unsuitable ground / surface conditions

- Travelling elevated over uneven ground

- Being hit by a falling object

- Being hit by vehicle or machine

- Operator error

- Misuse – operating outside of the machine's capabilities

- The platform being overloaded

- Being used in excessive wind

Powered access equipment relies on the strength and stability of the ground or surface which it is positioned or travelling upon. Failure to set up/operate on suitable ground can lead to instability which can lead to overturn.

Trained operators are crucial for safe MEWP operation, especially in the construction sector, which accounts for 31% of incidents over the past decade. Construction sites, often having multiple operations being carried out simultaneously, require meticulous planning and communication, particularly when MEWPs, cranes and other plant share the same work areas.

Reports in our accident portal have highlighted instances where MEWPs were struck by falling objects or other equipment whilst in an elevated position, leading to instability and overturn. Establishing safe exclusion zones both at ground and high level can mitigate the risks of the MEWP being impacted.

Machine selection is critical. It is important to note that indoor machines should not be elevated outdoors as there is a risk of overturn. When outdoors, you should always ensure an anemometer is used to measure the wind speed. You should never exceed the maximum allowable wind speed as specified by the manufacturer.

Furthermore, MEWPs should be operated on surfaces which are capable of supporting the MEWP safely, ground conditions should be thoroughly assessed during the planning stage. Geo-technical surveys are recommended for sites with uncertain ground capability.

The operator must ensure the MEWP is not used beyond its capabilities and should be aware of the types of ground conditions that it can be operated on. They should always be vigilant of any changes that can affect the ground conditions. Information on ground conditions is supplied in IPAF courses, IPAF safety guides, the ePAL app and guidance.

Certain larger MEWPS have restricted operating envelopes which affect outreach and working height depending on the axle/outrigger configuration and the load in the platform. Operating MEWPs outside of these parameters can potentially lead to an overturn. The operating envelope must always be checked from the ground controls prior to the MEWP being elevated from the platform.

An overloaded MEWP platform can lead to overturn. Modern MEWPs are fitted with load sensing systems to comply with international design standards, these systems can detect if a platform is overloaded. Overloaded platforms should always have the excess load removed promptly.

Analysis of MEWP Overturn Incidents for 2023

- In 2023, the USA recorded the joint-most incidents of MEWP overturns, followed by Canada and the Republic of Korea.

- The Construction industry saw a decrease from 12 incidents in 2022 to 10 in 2023.

- 3a type MEWPs were the most common type to overturn, with 11 incidents in 2023. 1b (vehicle) MEWPs recorded a decrease from 9 incidents in 2022 to 4 in 2023 (-56%). Conversely, 3b type MEWPs saw an increase from 1 incident in 2022 to 9 (fatal and major) in 2023.

- In the Construction industry, there were 7 fatalities and 3 major injuries related to MEWP overturns in 2023, a decrease from 8 fatalities and 4 major injuries in 2022. However, Facilities Management saw an increase in fatal incidents, with 7 fatalities and 2 major injuries in 2023, compared to 4 fatalities and 4 major injuries in 2022.

Overturns

In 2023, reports of MEWPs overturning decreased by 8% to 23 incidents, yet fatalities rose sharply by 39%. Nine countries reported these incidents, a 28.6% increase on 2022. Overall, 40 people were involved in incidents.

23

Reports

Decrease of 8% on 2022

9

Countries

Increase of 28.6% on 2022

32

Persons involved

Increase of 19% on 2022

24

Fatalities

Increase of 71% on 2022

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, push-arounds, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static)

Other

Unknown or no machine involved

Overturns by Industry Sector

Overturns by Location

Resources available:

Wind rating – using MEWPs in the wind

View on ipaf.orgGuidance on the assessment of ground conditions

View on ipaf.orgConsequence of overloading the platform

View on ipaf.orgNever attach a banner to a MEWP

View on ipaf.orgMEWP ground conditions Toolbox Talk

View on ipaf.orgAndy Access: Unsafe Ground

View on ipaf.orgAndy Access: Use Spreader Pads

View on ipaf.orgMEWP Catapult Effect

View on ipaf.org

Hit by Vehicle/Machine

MEWPs being hit by vehicles or machines has consistently ranked among the top 5 causes of accidents from 2021 to 2023.

Incorrect positioning of the MEWP inside an exclusion zone can lead to impact from passing vehicles, especially if parts of the MEWP protrude or extend outside the designated safe exclusion zone.

Adequately sized exclusion zones reduce the risk of a MEWP being hit by vehicles or machines. These protected areas need to be risk assessed to establish which form of protection is required, this may range from fencing, barricades, cones etc. Adequate signage and competent supervisors/ground control rescue personnel should be in place.

MEWP operators should remain vigilant when operating and always be aware of their surroundings, look up, look down, and look around before operating any function, consider if the action you are about to perform with the MEWP is going to take any part of it into potential danger and impact areas. MEWP operators should ensure that no part of the MEWP is able to extend or swing outside the exclusion zone. If there is a risk of collision, the operator should immediately lower the platform and report the issue.

When Operating:

- Ensure you are trained and familiarised with the MEWP’s controls, safety systems, and operating characteristics (e.g., tail swing of counterweight and configuration of articulated boom sections).

- Ensure all parts of the MEWP always stay inside the designated segregation zone.

- Maintain a clear view of the area while operating.

- When operating articulated booms, try to keep the lower boom or articulating knuckle raised to minimise the risk of collision with other equipment.

- Be aware of the MEWP’s movements and the location of other hazards in the area, including traffic, pedestrians, roads, and other plant

REMEMBER:

- Follow your risk assessment and safe work procedures.

- Maintain clear communications with the Spotter and follow directions and warnings when instructed.

- Be aware of your environment; look up, down, and around.

- Be aware of the MEWP rescue plan before entering the platform. Know who the nominated ground rescue person is.

Analysis of MEWPs Hit by Vehicles or Machines Incidents for 2023

- In 2023, the USA recorded the most incidents of MEWP Hit by Vehicles or Machines, followed by the UK and the Republic of Korea.

- The Construction industry recorded 9 fatal and major incidents in 2023, an increase of 125% on 2022 which saw 4 incidents.

- 3a type MEWPs were the most commonly involved, with 9 incidents in 2023, a slight increase on 2022 which saw 7 incidents. 3b MEWPs were the second most commonly involved in 2023 with 3 incidents, a decrease of 40% on 2022 which saw 5 incidents.

- In the Construction industry, there were 6 fatalities and 3 major injuries related to Hit by Vehicles or Machines in 2023, a significant increase from 0 fatalities and 4 major injuries in 2022.

Hit by Vehicle/Machine

In 2023, incidents involving MEWPs being hit by vehicles or machines saw fatalities jump by 117% compared to 2022, totalling 13. Over 50% of these incidents occurred in the construction industry, highlighting a significant area of concern.

14

Reports

Decrease of 6.7% on 2022

7

Countries

Decrease of 12.5% on 2022

17

Persons involved

Increase of 6% on 2022

9

Fatalities

Increase of 80% on 2022

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, push-arounds, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static)

Other

Unknown or no machine involved

Hit by Vehicle/Machine by Industry Sector

Hit by Vehicle/Machine by Location

Resources available:

Safe use of MEWPs in public areas

View on ipaf.orgSafe Loading and unloading MEWPs on public highways

View on ipaf.orgOperating MEWPs alongside roads

View on ipaf.orgStreet Smart Safety Campaign

View on ipaf.orgAndy Access: Be Street Smart

View on ipaf.orgAndy Access: Operating MEWPs Alongside Roads

View on ipaf.org

Mechanical/Technical

Mechanical breakdowns on powered access equipment do occur. The chances of machine breakdown increases when:

- Manufacturer’s instructions on inspections and maintenance are not followed

- Routine and periodical inspections required by legislation are not carried out

- Pre-inspections are not carried out correctly by the machine operators. An example could be a failure to identify a pre-existing fault

- The environment/location in which the machine is being used/operated/stored in

The data includes incidents where MEWPs have been impacted by other equipment leading structural and system failures.

Rental companies and end users should always adhere to maintenance guidelines from the manufacturer and statutory/periodic inspections that may apply in their region. Only competent individuals should conduct inspections and carry out maintenance.

Equipment operators play an important role in ensuring safety through familiarisation sessions, where trained operators are acquainted with control functions and safety devices by a demonstrator or by themselves if competent to do so. Powered access equipment varies in shape, size, and complexity, so conducting familiarisations is vital when operators are using unfamiliar equipment.

Powered access equipment should have evidence of a periodical inspection, this should be verified that it is in date before using the equipment.

Periodical inspections/thorough examinations should be carried out by a competent person.

Operators should perform a pre-use inspection before use, this includes a full function check and a check of the machines’ auxiliary systems. Not all machines are the same but the principles for inspection remain consistent. These inspections help identify potential safety hazards, such as fluid leaks and damage to electrical cables and hydraulic hoses. Once completed, the inspection should be recorded. The IPAF ePAL now allows for pre-use inspections to be recorded and shared.

If an operator identifies a defect during a pre-use inspection the machine should not be used.

The operator needs to:

- Isolate the machine – push the emergency stop buttons in and remove the key.

- Tag – Put a note or an isolation tag on the machine warning others that a fault has been identified and the machine must not be used.

- Report – The operator should report the issue to a supervisor. The machine should not be used until the defect has been rectified.

Operators of powered access equipment should always carry out their pre-use checks to confirm if the equipment is safe to use. These checks can be recorded in the operator's logbook or by the IPAF ePAL app.

Analysis of MEWP Mechanical or Technical Failures for 2023

- In 2023, most incidents originated from Sweden (28%) reports, while the US (17%), Italy (17%) and Germany (17%) were tied second.

- The Construction industry has proven to be the most common place for incidents involving MEWP mechanical or technical failures, evident in both 2023 and 2022. The Construction industry saw 6 fatalities and 2 major injuries. The Electrical sector submitted no reports in 2022, but there were 3 major injuries in 2023.

- The most common type of MEWP for mechanical or technical failures in 2023 was 1b (vehicle).

- In 2023, construction sites were the most common location for incidents to occur, followed by public areas and yards. The number of fatalities in 2023 was notably higher compared to 2022.

Mechanical/Technical

In 2023, IPAF reports of mechanical or technical failures rose by 83.3% to 11, with incidents up 50% involving 18 people. Originating from 8 countries, a 60% increase, there were 11 fatalities, up 83% from the previous year.

11

Reports

Increase of 83.3% on 2022

8

Countries

Increase of 60% on 2022

18

Persons involved

Increase of 100% on 2022

10

Fatalities

Increase of 400% on 2022

People involved by machine category

3b Mobile Boom

Self-propelled booms

1b Static Boom

Self propelled booms (outriggers), trailers, push-arounds, vehicle-mounted platforms

3a Mobile Vertical

Scissor lifts, vertical personnel platforms (mobile)

1a Static Vertical

Vertical personnel platforms (static)

Other

Unknown or no machine involved

Mechanical/Technical by Industry Sector

Mechanical/Technical by Location

Resources available:

Guidance for major inspections of mobile elevating work platforms

View on ipaf.orgManaging the safe condition of mobile elevating work platforms

View on ipaf.orgSafe on-site servicing of MEWPs

View on ipaf.orgAndy Access: Safe Workshop Servicing of MEWPs

View on ipaf.orgCAP Certification

View on ipaf.orgAndy Access: Don't Use a MEWP as a Crane

View on ipaf.org

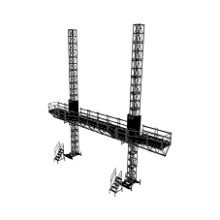

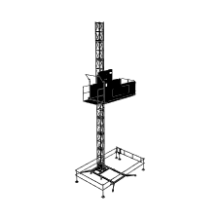

Mast Climbing Work Platforms (MCWPS) & Construction Hoists (CH)

In addition to gathering data on MEWPs, we also receive incident reports concerning MCWPs and CH.

MCWPs and CH are commonly used in the construction industry for carrying out building construction, repairs, maintenance, etc., to high rise buildings and other structures. The nature of their design allows for a long platform which is able to carry people, tools and materials often to heights where in some cases MEWPs cannot reach. It is common to see this type of equipment securely tied to buildings for months at a time.

The rise in reporting could be attributed to simpler reporting methods, such as through the ePAL app, making reporting anonymous and quick.

Incidents on this type of equipment are relatively scarce, this could be because the number of units in operation globally is far less compared to the number of MEWPs in service. However, when incidents do occur, it can often result in multiple casualties because they can carry more people.

Global standards

Global standards for MCWP and CH design and safe usage are undergoing revisions. EN1495 in Europe and Australian standards AS2550:16 (safe use) and AS1418:16 (design) are currently under review, aiming to enhance industry safety.

What can we do as an industry to reduce the number of incidents?

The safe and secure installation of a MCWP/hoist is critical to safety, this specialist equipment should only be installed by trained personnel.

Operators of this equipment should be adequately trained and familiarized with the equipment and pre-use inspections should always be carried out.

Inspections and maintenance

It is critically important that operators carry out their pre-use checks before using the equipment. Operators must never take safety for granted, having the attitude that nothing will happen to me can end in catastrophe particularly when working at height.

Global safe use standards require that statutory inspections are carried out at regular intervals by a competent person, these intervals are specified by standards and regulations. Once an inspection is carried out the equipment should have evidence of the inspection, this should always be verified by the operator as part of their pre-use inspection.

Operating

When MCWP and CH are being operated the platform occupants need to be aware of their surroundings and monitor the structural integrity of the equipment as well as the ties that hold the masts to the building. If there is any sign of danger the equipment must be fully lowered to the ground and the issue reported to the job supervisor.

Accident reporting: ipafaccidentreporting.org

Accident reporting is becoming a lot simpler with easier ways to report, especially now through the ePAL app. The increase in the number of reports could be due to people understanding that reporting can be anonymous and takes a matter of minutes.

Mast Climbing Work Platforms (MCWPS) & Construction Hoists (CH)

8

Reports

Increase of 300% on 2022

5

Countries

Increase of 150% on 2022

19

Persons involved

Increase of 850% on 2022

13

Fatalities

Increase of 400% on 2022

People involved by category

Mast Climbing Work Platform

Passenger Hoist

Goods Hoist

Transport Platform Hoist

Personnel Hoist

Mast Climbing Work Platforms (MCWPS) & Construction Hoists (CH) by Industry Sector

Mast Climbing Work Platforms (MCWPS) & Construction Hoists (CH) by Location

Resources available:

Mast Climbing Work Platform (MCWP) Thorough/Frequent Examination

View on ipaf.orgMCWP Loading Toolbox Talk

View on ipaf.orgAndy Access: MCWP and Hoist Rescue Plan

View on ipaf.orgMilestones

IPAF’s Key Milestones from 2023

Over 600,000 downloads of the ePAL app, over 90,000 users each month, pre-use check

IPAF’s ePAL app is your digital wallet for IPAF access licences and qualifications, including the PAL Card for MEWP, MCWP, and hoist operators. Quick and anonymous access to report any accidents and near misses involving powered access equipment.

ePALNew guidance has been produced on the safe use of MEWPs using pedestrian controls

Provide information for planning and managing MEWP operations, identifying main hazards in pedestrian control mode, risk control measures for pedestrian controls, and general global guidance to prevent incidents for those undertaking related tasks.

View nowIPAF members in 81 countries and regions worldwide with further growth anticipated

Download IPAF's Annual Report for an in-depth and insightful analysis of IPAF's global impact, showcasing significant achievements, innovative initiatives, and comprehensive data. Discover how IPAF is shaping the future of powered access worldwide.

View nowTargeted safety campaign – 2022 Don’t Fall for it

Please use this link to look at 'Falls From Height: Don't Fall For It' campaign material

View nowTargeted safety campaign – 2023 High Voltage

Please use this link to look at 'High Voltage: Electricity Can Kill, Stay Alert Stay Alive' campaign material

View nowTargeted safety campaign – 2024 Crushing can kill!

Please use this link to look at 'Crushing Can Kill: Stay Alert Stay Alive' campaign material

View now